XVIII. The Value Proposition of 3D Scanning

- Andrew Bessler, The George Washington University

In 2017, The British Museum uploaded the first complete 3D scan of the Rosetta Stone, allowing anyone worldwide to view and manipulate the ancient artifact from their computers. Published on Sketchfab, a 3D modeling platform website to publish, share, buy and sell 3D models, viewers now had free access to a high-resolution model of the stele, 218 years after its original discovery.1 Articles about the upload included phrases like “You no longer have to visit the British Museum in London to see the Rosetta Stone."2 As of November 2022, the object has been viewed on Sketchfab 380,000 times and downloaded 7,600 times.3 Comparing those numbers to the recorded 5.9 million visitors the British Museum had in 2017 alone, it is safe to say that visitors were still coming through the doors.4 As technology has progressed, it has become commonplace to find 3D objects like this embedded all across the web, enabling it to be seen far beyond the Sketchfab original.

Digitization projects like this are now a standard part of museum practice. Digitization is the process of creating a digital representation of an analog object.5 Since the 1960s and the creation of the Museum Computer Network, one of the primary goals of digital collections has been to share knowledge virtually between institutions.6 With public access to the internet, these collections became accessible beyond the researchers and management of museum staff. Digitization of 2D objects such as paintings and manuscripts can often be accomplished with cameras or document scanners. 3D objects, however, like the Rosetta Stone, require additional technology to capture and store the extra dimension.

The process of 3D digitization is accomplished with 3D scanning. A relatively new technology, 3D scanning emerged towards the end of the 20th century. The first 3D scanner was created in 1960 and used projected light to capture objects without color.7 The process was long and it struggled to achieve a high level of detail. In 1985, advancements in technology saw the use of lasers that could more quickly and accurately measure and capture details, including color.8 These new scanners were deployed in the industrial and animation fields with the first capturing measurements of physical spaces and the latter capturing human figures. Companies such as Faro and Cyberware Labs were integral in making the technology more affordable in the late 1990s, allowing the technology to enter more fields.9 2012 saw 3D scanners receive attention from museums with publications such as this one from Museums and the Web commenting on the “multitudes of opportunities ripe for exploration” within the museum space.10 Since then, 3D technologies have become a major talking point in the digitization of museum collections.

For Your Consideration

With so much advancement in such a relatively short time, the market for 3D technologies has never been larger. A variety of factors can determine what technology is best suited for a specific museum’s work. In terms of the collection, the scope of the project, both in terms of the size of objects as well as the number of objects awaiting digitization. Equally important are the material makeup of the object and the desired final product.11 For museum logistics, the choice may be determined by the price of the technology, which includes both hardware and software. Museum staffs vary widely, so hiring or training skilled professionals can shape a decision. This is by no means an exhaustive list to consider, but it provides the context for the following capturing technologies most deployed in museums.

Structured Light Scanning

Structured light scanners combine a camera, projector, and computer software to create 3D objects with both depth and color. They are typically either held in the hand or mounted on a tripod. These systems project a series of grid patterns and colors onto the object, using a dark background to identify the object’s edges.[^12] The software then uses trigonometric data based on the fixed position of the projector, camera, and light bouncing off the object to create a 3D object file.12 In general, structured light scanners are fast and can even be used on live subjects with minimal risk (compared to lasers). These scans can be incredibly detailed, but the light-based nature can lead to struggles with clear or reflective surfaces.13 The common need for an object to be rotated in place without moving makes this technology best suited for collections that have multiple objects of similar size and material. The learning curve in structured light scanning comes in the fine-tuning of settings within the software to obtain the ideal scan. Other considerations include the need for a space for the components to be set up, the ability to control light in that space, and having a computer powerful enough to process the data. Structured light scanners rarely exceed $30,000 and highly effective scanners can be purchased for as little as $699.14 Increases in price typically account for the accuracy of the camera and the effectiveness of accompanying alignment software.

Laser-Based Scanning

Laser-based scanners come in handheld and mounted forms and measure by projecting a line that has a definite length. This line is used to trigonometrically calculate the shape of an object while cameras on the device capture the color.15 These measurements are recorded as a point cloud and texture map that can be used to assemble the object in 3D space. The nature of laser scanners leads them to struggle with reflective and transparent surfaces, as the measurements are based on the reflection of light.16 They are incredibly fast and mobile, making them suited for scanning large objects that cannot be easily moved. Prolonged exposure to lasers can be harmful to body parts like the eyes, making them a potential hazard to living subjects. Laser scanner prices typically fall within the range of $200 to $50,000, with accompanying software on a subscription.17 As the price increases so do the accuracy and range of the scanner.

Photogrammetry

Photogrammetry is the process of creating a 3D model by taking images of an object and using overlapping points and mathematical angles to align the photographs.18 This is the process that the British Museum used to create the Rosetta Stone object.19 The software can use data from the image to rapidly stitch together thousands of images into a single, cohesive model. Depending on the quality of the camera, models created with photogrammetry can reach an incredibly high level of detail, though they may lose out on depth and texture relative to the number of pictures taken. Photogrammetry can be used on objects of any size including entire buildings, though this may require access to a camera mounted on a drone or aircraft.20 Scanning museum objects with this method is usually accomplished with a high-resolution digital camera, but even a standard smartphone camera can create a 3D model with little to no additional cost. As with other scanners, reflective objects can create glare that negatively affects results, but the use of a polarizing lens can reduce this.21

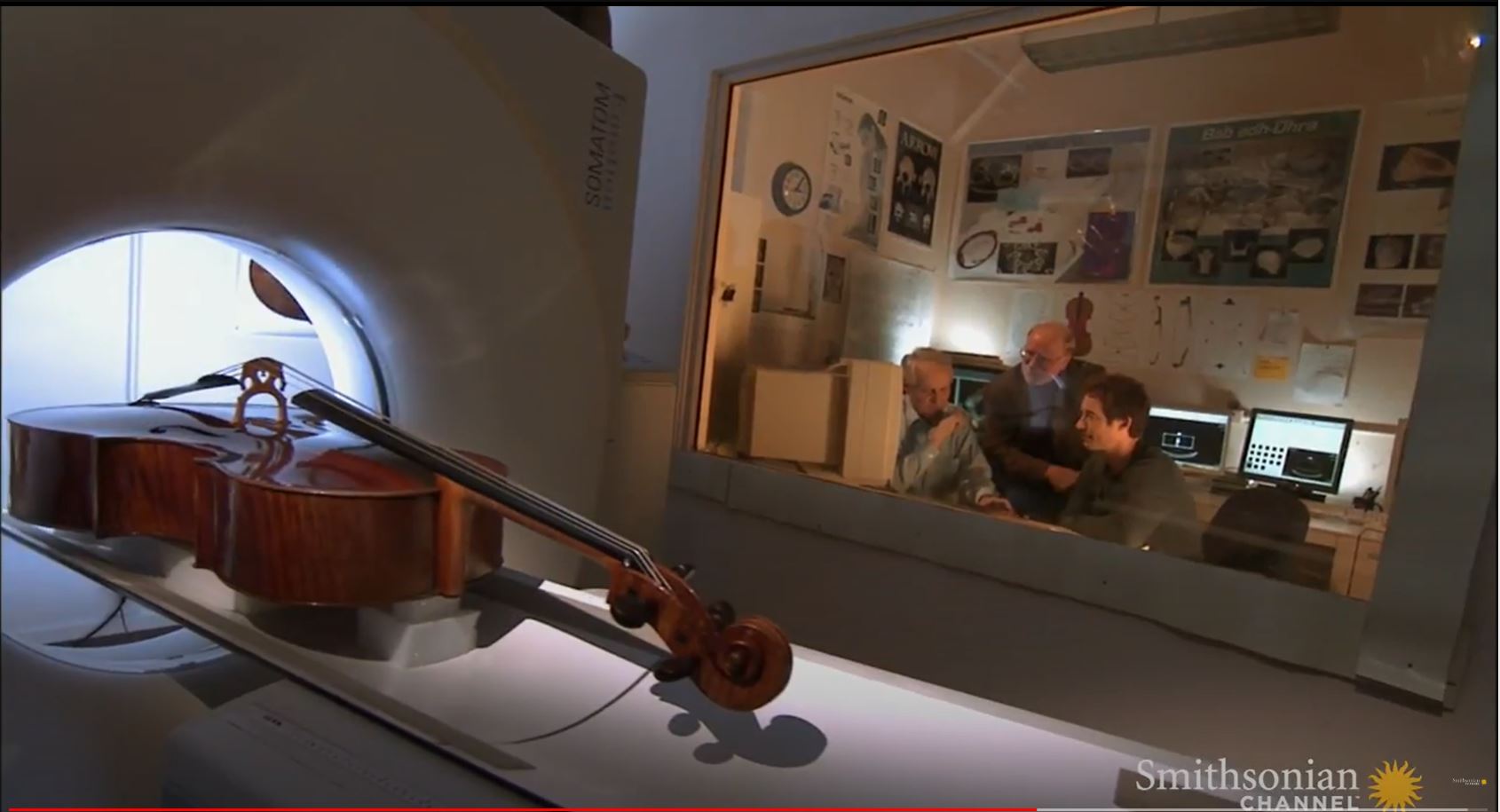

One parallel of photogrammetry is a computerized tomography or CT-Scan. The process involves the use of stitched x-ray images to create a 3D object.22 This type of scan requires technology ranging in price from $50,000 to $2.1 million.23 The machines are primarily medical tools, making them rare to find directly in museums. CT-Scans have been used by natural history museums around the world to create images of mummified remains without having to unwrap them. Other delicate objects like ancient pottery and glasswork can be viewed inside and out with little to no risk to their safety.

In addition to scanners, when working with 3D models there is the consideration of how best to manipulate and store the files. A powerful computer with substantial memory is a necessity to process scanned data and operate scanning software for the highest quality images.24 For example, a 4K resolution image used in photogrammetry takes up an average of 24 MB of space depending on the file format.25 Multiplied by 40, 100, or more, and the file can quickly become hard to manage. Sketchfab limits its basic users to uploads less than 100 MB, while business accounts can upload files up to 500 MB, so it is additionally important to know how to compress files.26

Even with accuracy increasing rapidly as the technology evolves, a scanned 3D model may require manual editing, sculpting, and color correction to achieve the most accurate result. This means the use of additional software and skills to do things like remove rendering errors or account for lighting discrepancies.27 However, more and more of this software is becoming free and open source, reducing the need to purchase proprietary software and increasing the number of users to teach and learn together.28 This makes 3D scanning more accessible to museums with limited budgets and less technical skill sets.

Taking the Leap

Once a scan is completed and a 3D model created, there is more a museum can do than simply upload it to Sketchfab. Since 2012, there has been a spotlight on 3D technologies in the museum field that has led to a diverse number of use cases from museums of all sizes. The following examples are intended to showcase the creative opportunities museums have undertaken using 3D scanning technology.

Conservation, Preservation, and Restoration

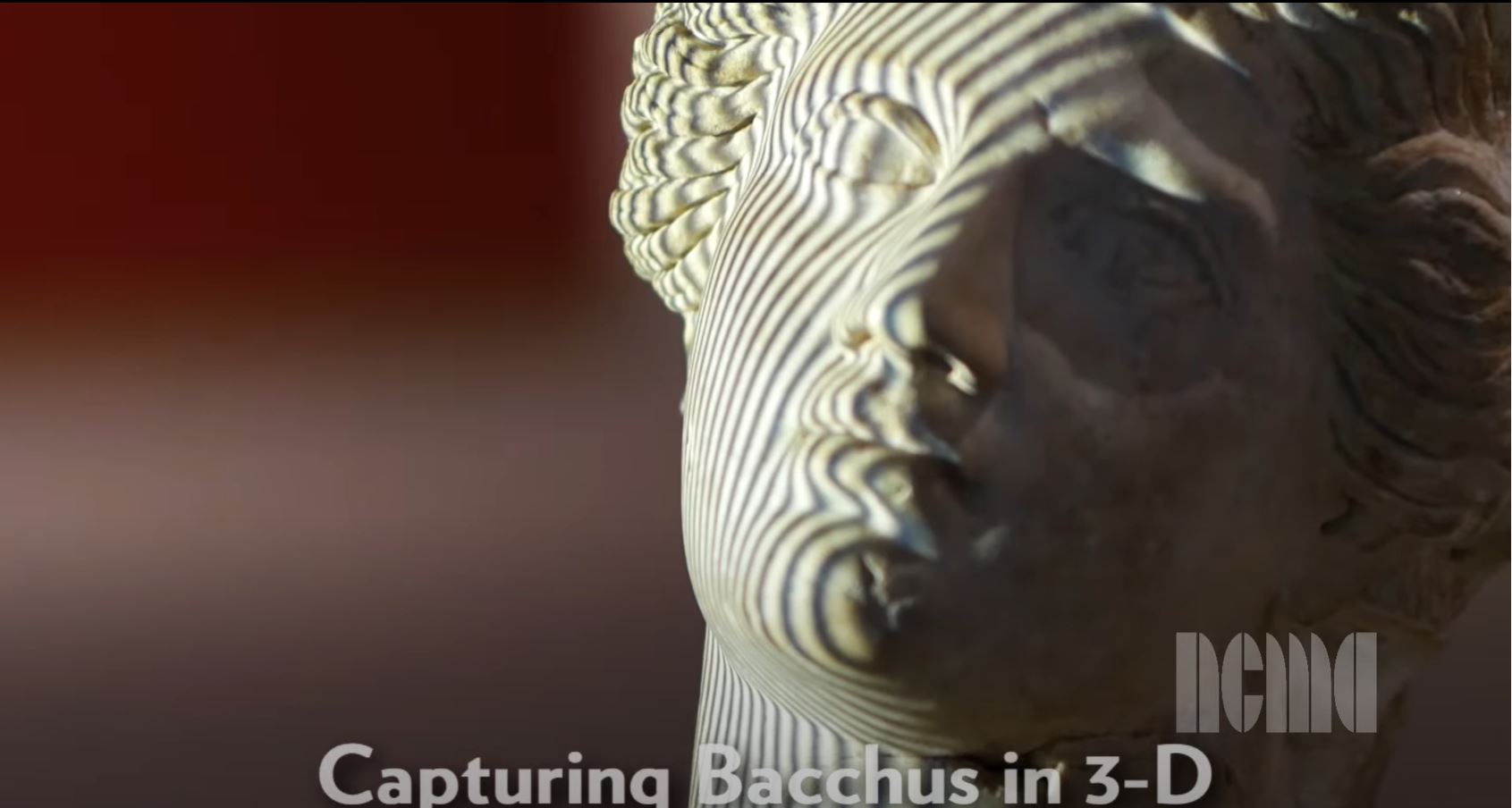

Museums can use 3D scanning for the conservation, preservation, and restoration of museum objects. In 2018, the North Carolina Museum of Art began a two-year conservation and restoration project on an Ancient Roman statue of Bacchus.29 The statue was in several pieces, and a sketch of the unbroken statue revealed it was missing pieces as well. Using a structured light scanner, the pieces of the statue were rendered as 3D objects, allowing the state of the statue as recovered archeological components to be preserved as well as paving the way for reconstruction. The scans, sketches, and a human model were used to create the statue’s missing arm and complete the statue.

Researchers used laser scanning to digitize the Qatar Museums' watercraft collection, creating 14 photo-realistic models with the use of photogrammetry and laser scan data.30 Typically stored on the water in a private dock, the watercraft ranged from 6m to 36m in length and had not been fully documented. The researchers used this as an opportunity to compare traditional measurement techniques to those of 3D scanners and found that scanners offered “exceptional speed, detail, and accuracy in the recording of complex watercraft."31 The data from the scans was used to create highly detailed and accurate naval sketches with cross-sections of each craft. The 3D models would go on to be used in animations featured within the public museum.

Research and New Discovery

In addition to preserving a collection, 3D scanning can reveal new insights into objects that had not or could not have been seen through other research methods. In 2015, the Smithsonian National Air and Space Museum began the arduous task of 3D scanning the Apollo 11 capsule that famously completed the first moon landing in 1969.32 The capsule had long been on display, but the delicate nature of the craft kept visitors at a distance, with only limited views of the interior. The goal of the project was to digitize the entire capsule in all its intricate detail, inside and out. What the staff was not counting on was finding “hand-written notes and markings in areas of the spacecraft that have been hidden from view for more than 40 years” inside the capsule.33 The scrawled text included calculations and a calendar that the staff had never known existed. What started as a conservation project turned into an entirely new research project.

Beyond surface details, scans can also be used to uncover the hidden histories of works of art, virtually peeling back their outer layers. In one case, the Rijksmuseum in Amsterdam was scanning Francisco Goya’s Portrait of the Spanish Judge Don Ramón Satué and found another unfinished portrait underneath.34 Based on the time period, it is theorized that the painting was covered up as canvas was expensive, and the original portrait was of Napolean Bonaparte’s brother, who had fled France during Goya’s time. While the truth may never be known for sure, the new layer adds narrative and context to the already magnificent piece.

When assessing the authenticity of a Qing Dynasty vase, the Walters Art Museum asked a radiologist to help them date the object.35 The museum had previously worked with the radiologist on mummified remains and wanted to see what a scan of the art piece might reveal. As it turned out, the piece had an even more complex design than originally believed, with interlocking components that explain how the piece was created. This example shows how 3D scanning can be used to reverse-engineer objects without having to physically deconstruct them. What the scans also revealed was a carefully completed and skillfully hidden repair at the base of the vase.36 As the piece was a gift for the royal family, it is considered unique for having a disguised defect as opposed to being flawless. Without the scans, these hidden gems would have remained undiscovered and unstudied.

Access and Accessibility

One of the main goals of digitization is the sharing of knowledge among both researchers and the public. 3D scanning has allowed more objects than ever to be shared online. The British Museum has 277 models on Sketchfab.37 each able to be viewed and downloaded for free. What is more, the files can be used in combination with 3D printers to create physical versions of 3D models. In the same 2013 article that covered 3D scanning, Museums and the Web also discussed the introduction of affordable 3D printers to the market.38 Originally developed for rapid prototyping in the fields of engineering, 3D printers use cheap materials to quickly create 3D models in accurate physical form.39 In most cases, the material is plastic, though some printers can print with materials such as clay or metal. The reduced cost of this technology allowed it to enter the museum field and unlock additional possibilities for 3D exploration.

3D prints can enhance the visitor experience in museums by combating the idea that touch should be forbidden when it comes to objects and artifacts.40 The Manacor Museum of History in Spain created 3D prints of 12 objects within their collection that had previously only been seen within glass cases.41 As an effort to combat the “hands off” ideology of museums, the chosen pieces were created in incredibly high detail so that visitors could experience the tactile feel of objects like hand-shaped pottery. They even went as far as to paint the printed objects to the point that they were nearly indistinguishable from their originals. This both protects and preserves the original objects while allowing visitors to experience the texture, size, and weight of objects they had only been able to view before.

Beyond general access to 3D objects, 3D technology also provides accessibility for individuals with disabilities. Prints like the ones in the Manacor Museum allow visually impaired individuals to experience the museum’s collection first-hand. The Uffizi Gallery in Florence invites visually impaired visitors to access famous paintings like Sandro Botticelli’s The Birth of Venus by featuring a 3D printed model of the painting next to the framed original mounted on the wall.42 The piece was created by exaggerating the shadows within the painting to add depth and texture that could be felt in the model.

In a similar vein, 3D scanning and printing can be used to reach people that are unable to attend a museum in person. The Victoria and Albert Museum brought their collection to children in the isolation ward of Great Ormond Street Hospital with touch screens and 3D printers.43 The children were shown the museum’s collection of sculptures and given workshops with 3D sculpting and modeling software. Using the museum’s collection as inspiration, the patients created their own works of art that the museum then 3D printed for each child to keep. The 3D printed material could also be kept sterile to protect the patients while they learned about the technology.

Community Engagement

While 3D scanning is important to the museum’s internal goals, it is equally important to involve the public with these tools. This builds connections with visitors and can even be used as a means of furthering the museum’s mission. For example, The Derby Museum of Making used scanners to promote digitization through a program that educated volunteers in the use of a handheld scanner.44 This was part of the ongoing process to digitize the full collection of historical tools and machinery that exemplify human innovation. One content expert trained a team that has published 154 objects to their online collection. Educating volunteers allowed the museum to go beyond the limitations of its own staff in digitizing its collection.

Inviting a community to participate can lead to entirely new results. The Metropolitan Museum of Art encourages its visitors to use their personal smart devices to create their own 3D models. Online, they offer guides and propose strategies for museum-goers to create their own models or remix existing models into their own works of art. In 2012, the MET had a two-day Hackathon centered on 3D scanning.45 They invited digital artists and technologists into the museum to explore the possibilities of 3D scanning. This invitation to technologists broadened the demographic of the museum beyond art enthusiasts, encouraging them to ideate on the ways the technology can be used.

Conclusion

While the dive into the expensive and complex technology of 3D scanning can be daunting, it is no less the perfect time to integrate 3D digitization into standard practice. The market for 3D scanners and printers has been opened to the public, making them more affordable than ever. 3D technology is widely available, and the community of educators and students is expanding all the time. Identifying the goal of any digitization project is key to choosing the right tools for the job. Understanding the limitations of an individual museum can be daunting, but hopefully from the examples, it is clear that there are many avenues to explore with even the most basic devices. 3D scanning provides an opportunity for museums to further their internal goals while also allowing the chance to connect to their audiences by sharing the collections they hold inviting the audience to participate in learning about the opportunities provided by 3D tools.

Notes

-

Katz, Brigit, “Interact With the First 3-D Scan of the Rosetta Stone,” Smithsonian Magazine, July 26, 2017. https://www.smithsonianmag.com/smart-news/interact-first-3-d-scan-rosetta-stone-180964205/ ↩︎

-

Furness, Dyllan, “The British Museum publishes the first 3D scan of the Rosetta Stone online,” Digital Trends Media Group, July, 20, 2017. https://www.digitaltrends.com/cool-tech/3d-scan-rosetta-stone/ ↩︎

-

“The Rosetta Stone,” Sketchfab, uploaded by the British Museum, July, 19 2017. https://sketchfab.com/3d-models/the-rosetta-stone-1e03509704a3490e99a173e53b93e282 ↩︎

-

“British Museum Annual Review 2017,” British Museum, 2018. https://www.britishmuseum.org/sites/default/files/2019-10/British_Museum_Annual_Review%202017_18.pdf ↩︎

-

Rajeev, “Museums Going Digital to Preserve Their Collections,” Managed Outsource Solutions Blog: Document Conversion, August 21, 2020, https://www.managedoutsource.com/blog/ ↩︎

-

Parry, R. 2007. “From the ‘Day Book’ to the ‘Data Bank’: The Beginnings of Museum Computing,” Recoding the museum: digital heritage and the technologies of change. Routledge, 15-31. ↩︎

-

Edl, Milan, Marek Mizerák, and Jozef Trojan, “3D Laser Scanners: History and Applications,” International Scientific Journal about Simulation, October 7, 2018, https://www.actasimulatio.eu/issues/2018/IV_2018_01_Edl_Mizerak_Trojan.pdf ↩︎

-

Edl, Mizerák, and Trojan 2018. ↩︎

-

Edl, Mizerák, and Trojan 2018. ↩︎

-

Neely L. and M. Langer, “Please Feel the Museum: The Emergence of 3D Printing and Scanning, in Museums and the Web 2013, ed. N. Proctor and R. Cherry (Silver Spring, Maryland: Museums and the Web 2013) January 31, 2013. https://mw2013.museumsandtheweb.com/paper/please-feel-the-museum-the-emergence-of-3d-printing-and-scanning/ ↩︎

-

Arkoudaki, Sofia, “6 Criteria for Selecting a 3D Scanner,” LinkedIn, February 20, 2018. https://www.linkedin.com/pulse/6-criteria-selecting-3d-scanner-sofia-arkoudaki/ ↩︎

-

Hamill, Scott, “Structured Light vs. Laser Scanning – A Thorough Comp arison,” 3DSourced, February 18, 2022. https://www.3dsourced.com/3d-scanners/structured-light-vs-laser-3d-scanning/ ↩︎

-

Kamani, Karan, “Types of 3D Scanning Technologies and 3D Scanners,” LinkedIn, June 29, 2020. https://www.linkedin.com/pulse/types-3d-scanning-technologies-scanners-karan-kamani/ ↩︎

-

“Best 3D Scanners (2022): In Every Use & Price Range,” 3DSourced, November 19, 2022. https://www.3dsourced.com/rankings/best-3d-scanner/#revopoint-pop-2 ↩︎

-

Kamani 2020. ↩︎

-

Hamil 2022. ↩︎

-

Best Scanners 2022. ↩︎

-

“Photogrammetry Guide 2022 – Definition, Advantages and Uses Explained,” 3DSourced, December 29, 2020. https://www.3dsourced.com/guides/photogrammetry-guide/ ↩︎

-

The Rosetta Stone 2017. ↩︎

-

Photogrammetry 2022. ↩︎

-

Spring, Adam, “Cross Polarised Scanning on a Shoe String,” December 17, 2017. https://adamspring.co.uk/2017/12/17/cross-polarised-scanning-shoe-string-photogrammetry/ ↩︎

-

“Computed Tomography Scanning,” Field Museum, accessed November 3, 2022. https://www.fieldmuseum.org/science/research/area/conserving-our-collections/examination-documentation/computed-tomography-ct ↩︎

-

“How Much Do CT Scanners Cost?” DirectMed Parts & Service, September 18, 2020. https://directmedparts.com/how-much-do-ct-scanners-cost/ ↩︎

-

Glawion, Alex, “Autodesk Maya System Requirements & PC Recommendations,” CGDirector, June, 17, 2022. https://www.cgdirector.com/autodesk-maya-system-requirements/ ↩︎

-

“How Large is a 4K Image?” PointerClicker, January 6, 2022. https://pointerclicker.com/how-large-is-a-4k-image/ ↩︎

-

“Plans,” Sketchfab, accessed November 12, 2022. https://sketchfab.com/plans ↩︎

-

“Top 10: Best 3D Modeling Software of 2022 (Some Are Free),” All3DP, April 4, 2022. https://all3dp.com/1/best-free-3d-modeling-software-3d-cad-3d-design-software/ ↩︎

-

“The Top 10 Best Photogrammetry Software 2022 (4 are Free!),” 3DSourced, November 19, 2022. https://www.3dsourced.com/3d-software/best-photogrammetry-software/ ↩︎

-

Rocheleau, Caroline, “Bacchus Under Structured Light,” North Carolina Museum of Art, February 28, 2018. https://ncartmuseum.org/bacchus_under_structured_light/ ↩︎

-

Cooper, J.P., A. Wetherelt, C. Zazzaro, and M. Eyre, “From Boatyard to Museum: 3D laser scanning and digital modeling of the Qatar Museums watercraft collection, Doha, Qatar,” International Journal of Nautical Archaeology, 47: 419-442. May 16, 2018. https://doi.org/10.1111/1095-9270.12298 ↩︎

-

Cooper J 2018. ↩︎

-

Needell, Allan, “Apollo 11: The Writings on the Wall,” National Air and Space Museum, February 11, 2016. https://airandspace.si.edu/stories/editorial/apollo-11-writings-wall ↩︎

-

Needell 2016. ↩︎

-

Dobrzynski, Judith, “Technology Payoff: A New Goya Is Discovered,” ArtsJournal, September 21, 2011. https://www.artsjournal.com/realcleararts/2011/09/new_goya_discovered.html ↩︎

-

Burmahl, Beth. “Advanced Imaging Aids the Quest to Authenticate or Refute the Value of Ancient Artifacts,” Radiology Society of North America, February 11, 2019. https://www.rsna.org/news/2019/february/value-of-ancient-artifacts ↩︎

-

Burmahl 2019. ↩︎

-

The Rosetta Stone 2017. ↩︎

-

Neely 2013. ↩︎

-

“A Detailed History of 3D Printing,” 3DInsider, accessed November 27, 2022. https://3dinsider.com/3d-printing-history/ ↩︎

-

Cooper, Catriona. “You Can Handle It: 3D Printing for Museums.” Advances in Archaeological Practice 7, Issue 4, 443–47, Cambridge University Press, October 22, 2019. https://doi.org/10.1017/aap.2019.39 ↩︎

-

“Manacor Museum Creates 3D Printed Exhibit Replicas,” 3DPrinting, July 6, 2018. https://3dprinting.com/news/manacor-museum-creates-3d-printed-exhibit-replicas/ ↩︎

-

Barnes, Sarah, “Art Museums Are Creating 3D Versions of Paintings for Visually Impaired People To Touch,” My Modern Met, January 22, 2021. https://mymodernmet.com/museum-3d-art-accessibility/ ↩︎

-

Flowers, Alex, “Taking sculptures for a walk: 3D printing and museum outreach,” Victoria and Albert Museum, April 6, 2018. https://www.vam.ac.uk/blog/digital/taking-sculptures-for-a-walk-3d-printing-and-museum-outreach ↩︎

-

Clohessy, Eilish, “Co-Producing a 3D Imaging Programme at Derby Museums,” Sketchfab Blog, December 12, 2017. https://sketchfab.com/blogs/community/ ↩︎

-

Undeen, Don, “3D Scanning, Hacking, and Printing in Art Museums, for the Masses,” The MET, October 15, 2013. https://www.metmuseum.org/blogs/digital-underground/posts/2013/3d-printing ↩︎